by James Williams

When there is a flood or heavy rain, sump pumps are there to help make sure your basement is dry by collecting the water. However, if during operation the power goes out or an accident happens, all the collected water will end up flowing back.

How do you prevent this? With a sump pump check valve, of course. These are a must-have for any sump pumps but finding the right one can be difficult.

Thus, this article aims to help you find the best sump pump check valve for you. Soon you won't have to worry about the backflow of water in your pump anymore.

Contents

People might ask why they should go through so much trouble picking out a check valve. A good check valve has some notable advantages.

Check valves only allow water to flow in a single direction. They are self-automated, so do not require user input. Preventing backflow is important as otherwise, your basement will remain wet after rain.

A check valve regulates the pressure in a sump pump. It minimizes pressure differential so the flow of water in a pump is steady. This is important for preventing water damage and impairment of your pump. So, you can vastly increase the product's lifetime.

Sump pumps are noisy. The primary cause of this is water hammer which occurs when the water is suddenly forced to change direction. Check valves help to reduce this. Water hammer can also damage your pump. So, proper installation will keep it in the best shape.

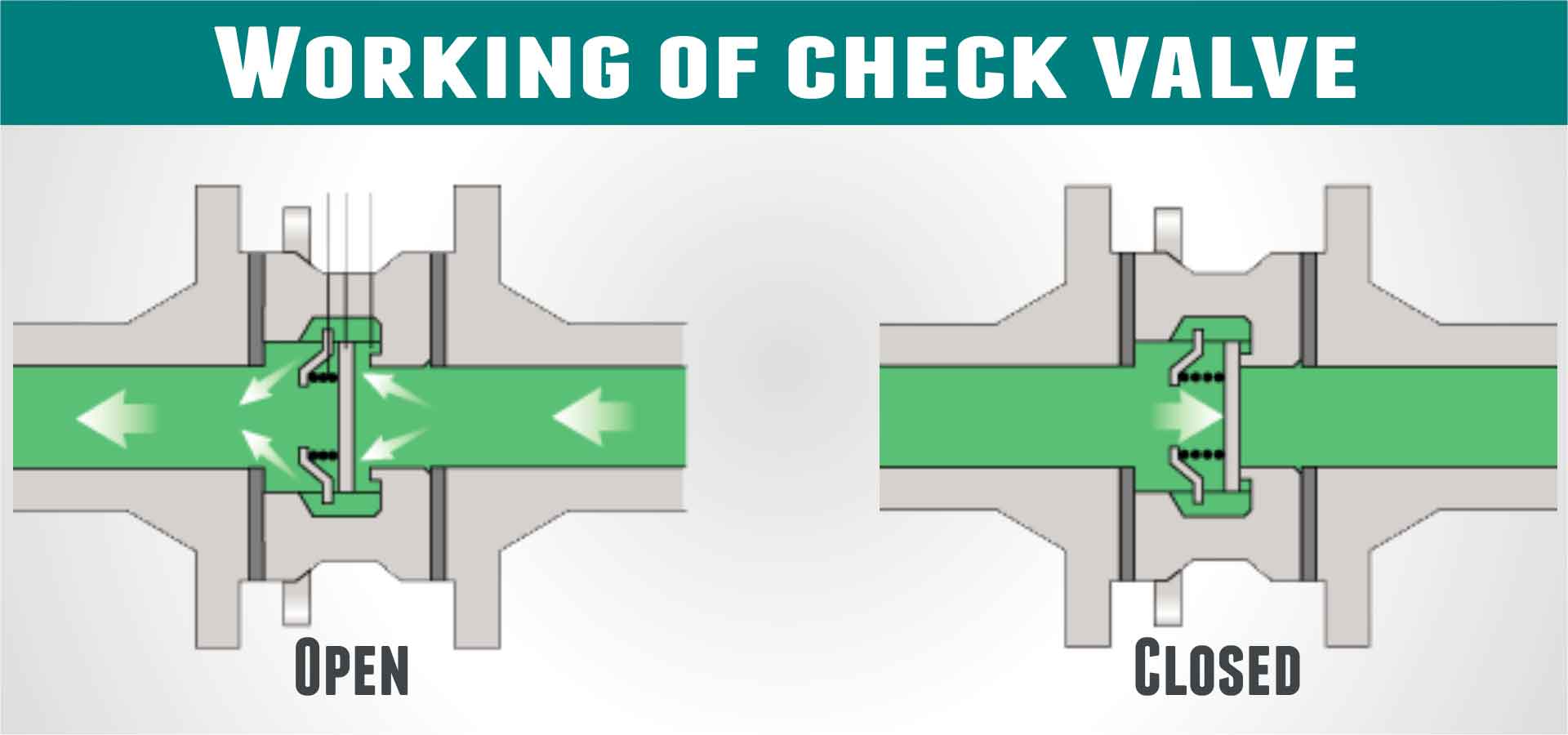

For those who are curious as to how a check valve works, we've included a small summary regarding this. To understand, you need to first learn about a term known as 'cracking pressure'.

Typically, water will move from a high-pressure area to a low-pressure one. All check valves have a unique 'cracking pressure' which is the minimum pressure difference needed for water to pass through.

When water is flowing normally, it will have enough pressure to flow through the valve. So it acts as a normal pipe. However, when there is backflow, the water pressure is typically lower than the cracking pressure.

An internal mechanism is employed to block off the water. This prevents backflow. The mechanism is unique to the type of item you are using.

A wide variety of different mechanisms are employed to prevent backflow. Some of them are listed below:

A disc gate is used which is connected to a spring. When the pressure differential is higher than the cracking pressure, the spring is overcome, and the gate is forced open.

During backflow, the spring causes the gate to stay closed. So water does not pass.

This type consists of a ball on the sealing seat and can be either spring-loaded or free-floating. Higher pressure water flow pushes the ball from the sealing seat which allows normal flow.

When there is backflow, the ball is placed back into the sealing seat. If the pressure of the water is below the cracking pressure, the ball won't move and so it seals the way.

A swing check valve makes use of a hinged door. The normal flow of water pushes the door open while the door remains closed during backflow.

So, to summarize:

We have picked out6 check valves. We consider these to be the best picks and we'll examine each one of them.

We start strong with a product from Campbell. They are well known for making high-quality check valves.

The Brady MfrPartNo 0823-15C is of 1.5-inch size. This is a great benefit as most pumps have a similar size rating. So this item is compatible with many sump pumps. Another helpful aspect is how easy it is to attach to your pump since it features a Slip X Slip connection.

You can use pumps that have a water pressure of 150 PSI. It is constructed out of clear PVC. Thisis an amazing material to use for your check valves due to its longevity and durability. Since the PVC is clear, you can easily monitor it if needed.

It operates using a strong spring located inside the valve. The spring is used to detect excess water pressure which signals the check valve to open in one direction only. So, water is redirected away which prevents it from coming back.

This whole operation is noiseless, so you won't have to worry about constant clicking noises.

A problem we did find with the sturdy spring. It often does not detect flooding when attached to low-pressure pumps. If you have a high-pressure pump, you will benefit greatly from installing this check valve.

One of the worst things that can happen to you when buying a check valve is finding out that it doesn't fit your sump pump. The Wayne pumps 66005 is designed to work with a majority of pumps. It has a threaded male end of 1 ½ inches adapters and an outflow shoulder end of 1¼ inches.

All the adapters ensure that your check valve fits securely with your sump pump. This item also works with high water pressure and temperature. You can thank the unit's durable top-grade PVC construction for that. It will last for years.

The installation is quite easy and it comes with the necessary parts. Wayne pump's valve action is effective. It easily detects and prevents the backflow of water. The operation is also very quiet. While it isn't 100% noiseless, it won't bother you much.

The threaded parts are quite sensitive. So, be careful not to damage the parts when installing it. This can make the fit not as secure. Other than that, this is a great pick simply because of how many pumps it can work with.

If the name didn't give it away, the Raybend check valve's operation is 100% noiseless. A spring-loaded flapper is present in this check valve which eliminates the water hammer noise that many users find irritating.

This check valve works with 1.5-inch pumps. Since such pumps are very common, this item is usually a great match most of the time. Purchases of this unit also include the clamps for installation. These clamps are made of stainless steel and so are sturdy as well as resistant to corrosion.

The body is also made out of ABS. While a bit heavier than the other options discussed above, it is much more durable. A clear section is also present so that you are able to monitor water movement.

Installation is very easy for this particular model. The connections being made out of stainless steel ensure that they don't rust and grow weak. While it works with high temperatures of water, it is meant for weaker pumps at 80 PSI.

When the sump pump is located near you, the water hammer noise can be quite loud. For those cases, the Raybend is an amazing pick simply because of the noiseless operation.

If you have a tight budget and require a check valve, perhaps Jackel's check valve will suffice. This is one of the best budget picks on this list. Since it makes use of the standard 1.5-inch size, you can use the unit with a variety of pumps.

Stainless steel clamps are included with this check valve. Connectors being made out of stainless steel are a great benefit. They are rust and corrosion resistant and the presence of water will usually cause the connectors to rust and weaken, these do not. So, you won't have to replace this valve often.

High-grade ABS material is used to construct the body of this item. The material is strong and there is no danger of decaying.

This vertical check valve makes use of a rubber flapper to prevent backflow. This flapper is very durable and can work with higher pressures of water. The operation isn't completely noiseless but it is quieter than most.

For its price, this unit has great performance and good quality construction. Installation is hassle-free which is another reason to pick this.

A high-quality PVC check valve, the Zoeller 30-0181 is one of the best products available for purchase. The unit is designed to be effective at its job and as user friendly as possible.

The first thing to note about it is that themodel comes in a 1.5-inch size. You can connect it to most sump pumps. Furthermore, installation is easy as it makes use of a slip x slip connection. You don't need to fumble with the installation and it is easy to remove too if needed.

Are you afraid that your check valve will be noisy? No need to worry as this unit is designed to operate in complete silence. The only sound it emits is the indicator showing that it is working. No water hammer noise is produced when using this.

Clear high-grade PVC is used in the construction. Thisis a very good material as it is strong and water-resistant. Since the PVC is clear you can also monitor the water movement.

The flapper used in this particular item is very strong. It can withstand high temperatures and reduces water hammer. You don't need to worry about it breaking as the product has a long life span.

It's hard not to recommend this check valve as it is so good. The item has it all- durability, functionality, and affordability.

The final pick on our list is another check valve from Campbell. This one has a size of 2 inches. While the most commonly used size is 1.5 inches, 2 inches is good for stronger pumps. The item is made to work with pumps that have higher flow rates or a greater amount of pressure.

To make sure the model can withstand high water pressures, heavy-duty PVC is used in its construction. The pumpis quite durable. There is also a clear section so that you can monitor water movement and see if it is working properly or not.

Stainless steel connectors are used to secure this check valve to your sump pump. These are very strong and rust-resistant. The installation of this thing is hassle-free.

You don't have to worry about water hammer and noise. The flapper is designed to prevent those and work as silently as possible. It is also very sturdy to withstand high water pressure.

The only problem we found that this item is a bit expensive. While it has a long lifetime, replacing it is not cheap. If you don't have an issue with that, we would recommend installing this Campbell check valve.

So you now might ask how you would pick the right check valve. There are a few key factors that buyers need to look out for.

How often your area gets flooded will determine the frequency of use of your check valve. If flooding is common, your check valve will see a lot of use. In that case, you want an item that lasts long and doesn't require to be replaced often. You don't want it to suddenly stop working during an inopportune time

You will want to look out for durable check valves. High-grade PVC construction is preferred since PVC does not decay and is strong. They have a long life which is an important factor if your area sees a lot of flooding.

The size of your pump matters. If your check valve does not match the size of your pump it will not be secure. Either it will not work properly or end up damaging your pump. So you need to make sure the check valve size accommodates the pump.

Customers might ask- what size check valve is the best? 1.5 inches is the most commonly seen pump size so buying a 1.5-inch check valve is a good bet. However, you should always check your pump size before deciding what size check valve to buy.

While some check valves come with adapters to help connect to different sized pumps, the connections aren't always as secure. Furthermore, the adapters can get damaged and it is often difficult to find an appropriate replacement which further increases costs.

If your pump is near you, you will usually be exposed to loud noises. Some check valves are very noisy and if you are irritated by water hammer noise, you should avoid those. Not all check valves offer the same level of noise reduction so keep that in mind.

Some check valves have a clear section that allows you to see the movement of water. You can use it to judge if the pump is working to your liking. If you frequently check out your pump due to flooding, having a check valve with a clear PVC section will help.

Other check valves do have indicators that let you know whether they are working or not. However, a clear section also allows you to easily troubleshoot and identify problems with your pump or check valve.

The water pressure and flow rate of your pump are important to consider. Some check valves are made to work with weaker pumps. If the flow rate is too high the item might not be able to do its job and prevent backflow. It might even get damaged.

There are two things to consider in this case. One is that the check valve must be strong and be able to withstand the pressure. The other is that the internal mechanism of the item (usually a flapper) must be able to block off the water properly.

Always check the pressure rating on check valves. An incompatible unit will just end up increasing your replacement costs. For weaker pumps, you should also consider this. Sometimes the internal mechanism of stronger check valves won't detect backflow. So it ends up not working.

They are usually placed near the sump pump or the sump pit. That is to prevent too much water from getting clogged and interfering with the operation. A general rule of thumb is that the check valve should be 10 inches above the sump pit to ensure proper operation.

If your area isn't prone to flooding or doesn't experience heavy rain, you can make do without a check valve on your sump pump. However, a check valve improves your pump's performance and lifetime. Although the item is not required, it is highly recommended to get one for the benefits it provides.

You should replace your check valve whenever you see signs of it going bad. Test the valve every 9 to 12 months. If you see any damage or if it's not working properly, it is recommended to replace the item as quickly as possible. This prevents any potential damage to the pump.

Check valves can go bad. This can be due to leaks or connectors getting damaged. Faulty connections are also a common reason as to why they go bad. Regularly check for leaks and tighten the clamps. PVC cement can also help.

The prominent issue is that the backflow of water will occur. Instead of the sump pump keeping your basement dry, it will end up flooding it. Other issues include water hammering which will damage your pump and reduce its lifetime. This is often accompanied by large noises.

You can use the clear section in some check valves. A reference arrow is present to show the correct direction of water flow. If you spot abnormalities in the flow, it is probably a sign of the unit going bad. Other ways of knowing include the operation suddenly becoming noisy, or leaks.

Zoeller 30-0181 PVC Plastic Check Valve, 1-1/2 Inch - Etsy Link

Superior Pump 99555 Universal Check Valve, Plastic, Fits all 1-1/4-Inch or 1-1/2-Inch MIP - Etsy Link

Jackel Sump Check Valve (Model: DJ-545) - Etsy Link

Little Giant 599059 CV-114/112 Check Valve - Etsy Link

Campbell Check Valve Quiet CLR1.5 by Brady MfrPartNo 0823-15C, White - Etsy Link

Wayne Pumps 66005-Wyn Check Valve, PVC - Etsy Link

Zoeller 30-0043 50 psi PVC 2-Port Check Valve, 2" - Etsy Link

Smith-Cooper International CV30L Series Brass Check Valve, Potable Water Service, NPT - Etsy Link

Zoeller M53 Mighty-mate Submersible Sump Pump, 1/3 Hp - Etsy Link

Zoeller 10-4011 High Water Alarm with battery - Etsy Link

Zoeller 30-0181 PVC Plastic Check Valve, 1-1/2 Inch - eBay Link

Superior Pump 99555 Universal Check Valve, Plastic, Fits all 1-1/4-Inch or 1-1/2-Inch MIP - eBay Link

Jackel Sump Check Valve (Model: DJ-545) - eBay Link

Little Giant 599059 CV-114/112 Check Valve - eBay Link

Campbell Check Valve Quiet CLR1.5 by Brady MfrPartNo 0823-15C, White - eBay Link

Wayne Pumps 66005-Wyn Check Valve, PVC - eBay Link

Zoeller 30-0043 50 psi PVC 2-Port Check Valve, 2" - eBay Link

Smith-Cooper International CV30L Series Brass Check Valve, Potable Water Service, NPT - eBay Link

Zoeller M53 Mighty-mate Submersible Sump Pump, 1/3 Hp - eBay Link

Zoeller 10-4011 High Water Alarm with battery - eBay Link

If you are still confused and need an opinion on the best sump pump check valve, we would personally recommend the Zoeller 30-0181. It checks all the requirements of a good check valve- noise reduction, solid construction and works with a variety of pumps. The item is also very affordable.

Our second pick would be the Wayne Pumps 66005 simply for how good of a budget pick is. The only problem we've mentioned is that you need to be very careful with the installation.

About James Williams

Hi, This is James from HomerDIY. I have great experience in writing about everything related to Pump and DIY tools. For the last few years, I am researching the different types of tools and sharing my opinion on this blog.

|

|

|

|